Understanding the Tevo Tarantula An Overview

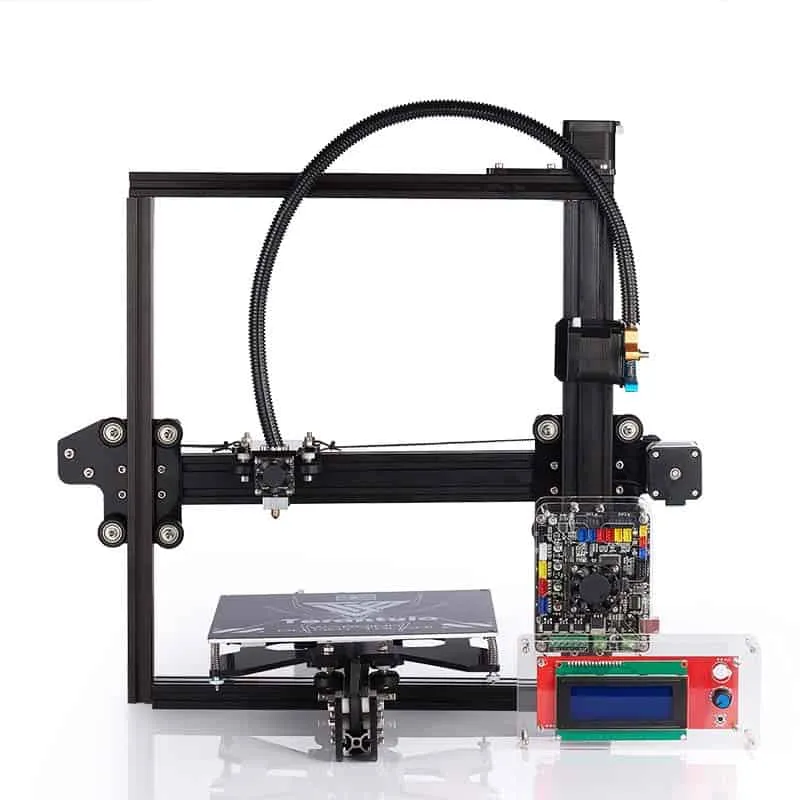

The Tevo Tarantula has become a popular entry-level 3D printer in the DIY community. Known for its affordability and ease of assembly, this printer offers a great starting point for anyone looking to explore the world of 3D printing. Understanding the parts that make up the Tevo Tarantula is crucial for maintenance, upgrades, and troubleshooting. This comprehensive guide breaks down the essential components, helping you familiarize yourself with the printer and ensure optimal performance. Whether you’re a beginner or an experienced user, knowing your printer inside and out will enhance your 3D printing experience, enabling you to tackle projects with confidence and precision. The Tevo Tarantula offers a fantastic blend of accessibility and functionality, and this guide is designed to help you make the most of it.

Key Components of the Tevo Tarantula

The Tevo Tarantula is comprised of several key components that work together to bring your 3D designs to life. Each part plays a crucial role in the printing process, from the structural frame to the intricate electronics. This section offers a detailed overview of each major component, providing insights into their functions and importance. Understanding these key parts will provide you with a solid foundation for maintaining, upgrading, and repairing your Tevo Tarantula. This understanding is essential for effective troubleshooting and optimizing the printer’s performance. The following sections will delve deeper into each component, offering specific details and practical advice to enhance your 3D printing journey.

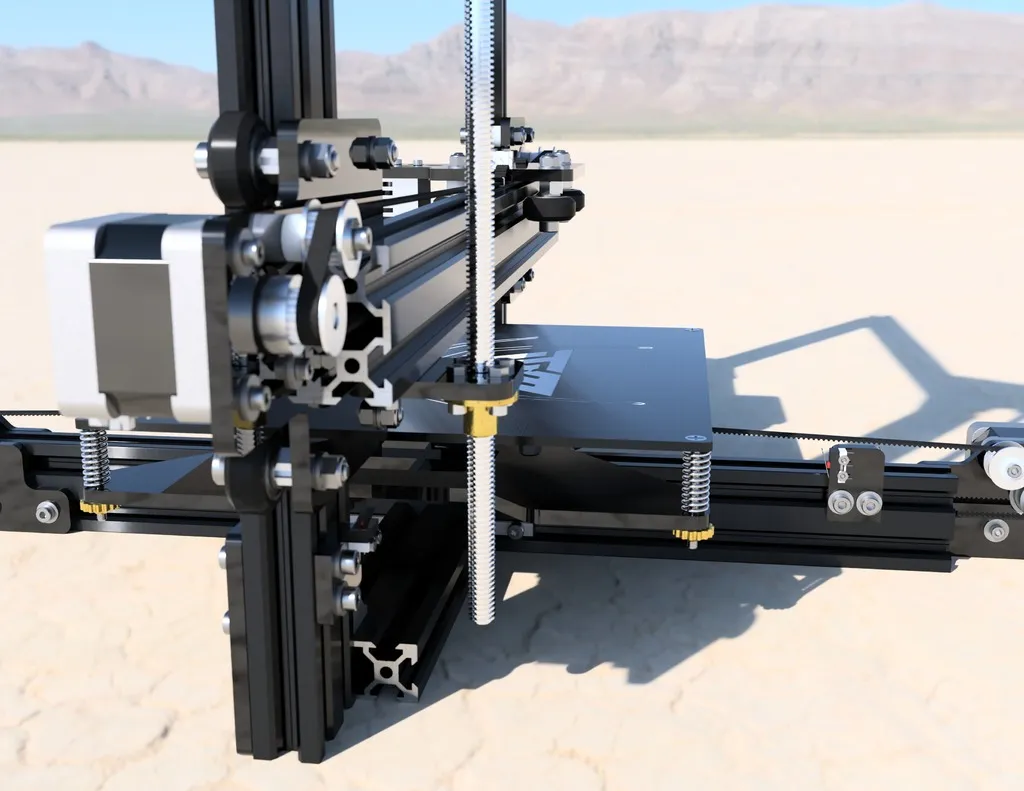

The Frame and Structure

The frame of the Tevo Tarantula provides the structural support for the entire printer. Typically constructed from aluminum extrusions, the frame must be sturdy and stable to ensure accurate printing. The rigidity of the frame directly impacts the quality of your prints, as any flex or wobble can lead to imperfections. Proper assembly and regular checks of the frame are vital to maintain print quality. Ensure that all screws are tightened securely and that the frame is level. If you plan to upgrade your printer, consider reinforcing the frame with additional supports. This will increase stability, allowing for faster print speeds and improved print quality. A well-maintained frame is the cornerstone of a reliable 3D printing setup.

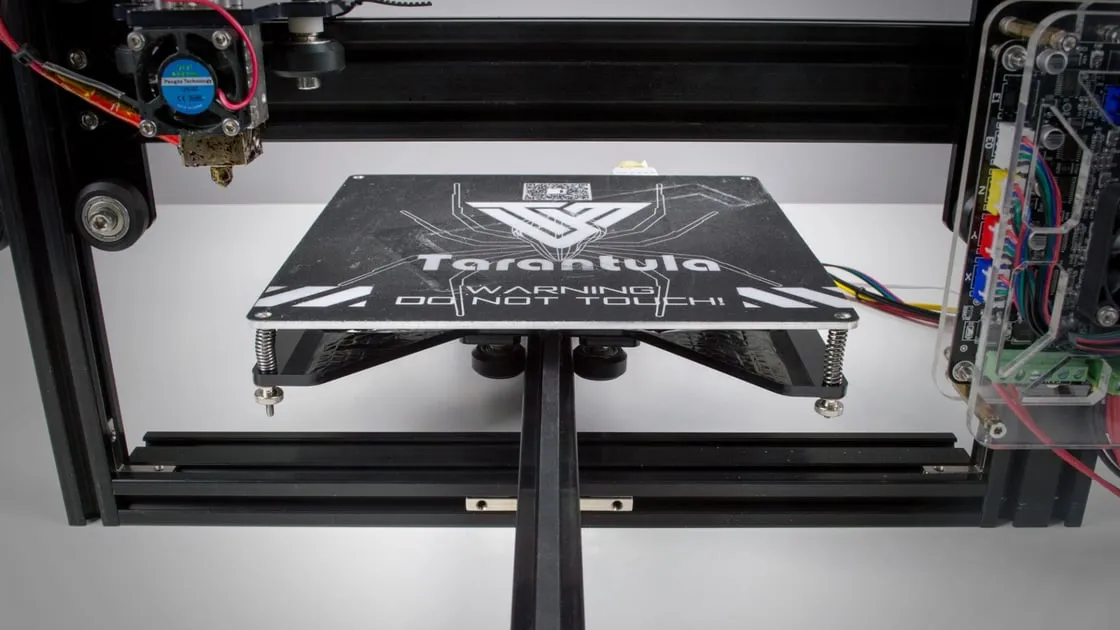

Bed and Print Surface

The print bed is where your 3D models take shape. It moves along the Z-axis and provides the base for your prints. The Tevo Tarantula typically comes with a heated bed, essential for printing materials like ABS, which require a warm surface to adhere properly. Consider upgrading to a glass or PEI surface for improved print adhesion and easy removal of finished prints. Make sure to calibrate the bed level frequently to ensure the first layer of your prints adheres correctly. Uneven bed levels can result in poor print quality, warping, and failed prints. Inspect your print surface regularly for damage. A clean and well-maintained print bed is crucial for successful 3D printing. Always clean the bed before printing to remove any debris.

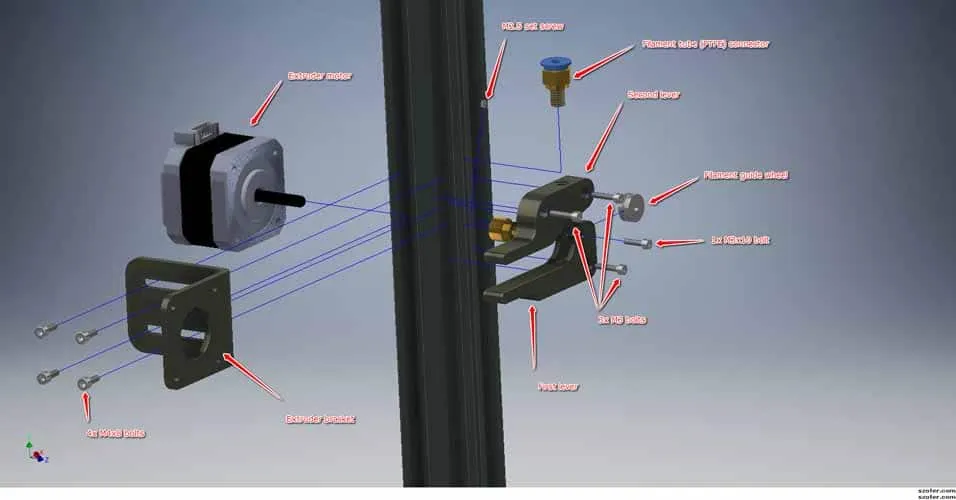

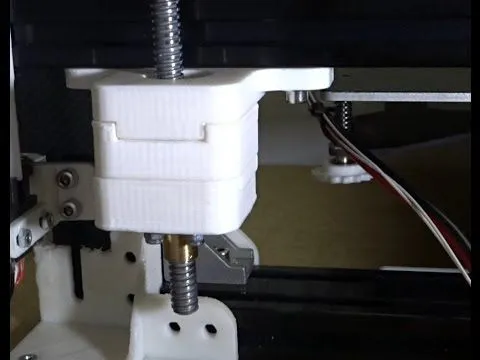

Extruder and Hotend

The extruder is responsible for feeding filament into the hotend, where it melts and is deposited onto the print bed. The hotend consists of a heater block, a heat break, and a nozzle. The nozzle is the part that extrudes the molten filament. Upgrading to an all-metal hotend can improve temperature stability and allow you to print a wider range of materials. The extruder’s performance has a direct impact on print quality and reliability. Keep your extruder clean and free of debris. Regularly check the nozzle for clogs, and ensure the hotend reaches the correct temperature. If you encounter issues, check the extruder gear tension. Proper maintenance will prevent clogging and uneven extrusion, ensuring smooth and precise printing.

Nozzle and Filament

The nozzle is a critical part of the hotend, responsible for precisely depositing molten filament onto the print bed. Different nozzle sizes are available, affecting print speed and resolution. A smaller nozzle provides finer details but slower printing, whereas a larger nozzle is faster but produces rougher prints. The choice of filament significantly impacts print quality and the types of projects you can undertake. Common filaments include PLA, ABS, PETG, and TPU. The filament’s diameter (typically 1.75mm) must match the extruder. Proper filament storage is critical to prevent moisture absorption, which can lead to print defects. The nozzle can wear over time. Consider replacing it regularly to maintain the quality of your prints.

Stepper Motors and Drivers

Stepper motors control the movement of the printer’s axes (X, Y, Z, and extruder). They convert electrical pulses into precise mechanical movements. Stepper drivers translate commands from the control board into signals for the stepper motors. Upgrading to quieter drivers can significantly reduce the noise generated by your printer. Ensure that your stepper motors are properly calibrated and that the belts are tensioned correctly. Incorrect settings or loose belts can lead to print inaccuracies and failed prints. Over time, stepper motors can wear out. Monitoring their performance and replacing them when needed is essential for maintaining print quality. A smooth running of the stepper motor contributes to a better output of the 3D printer.

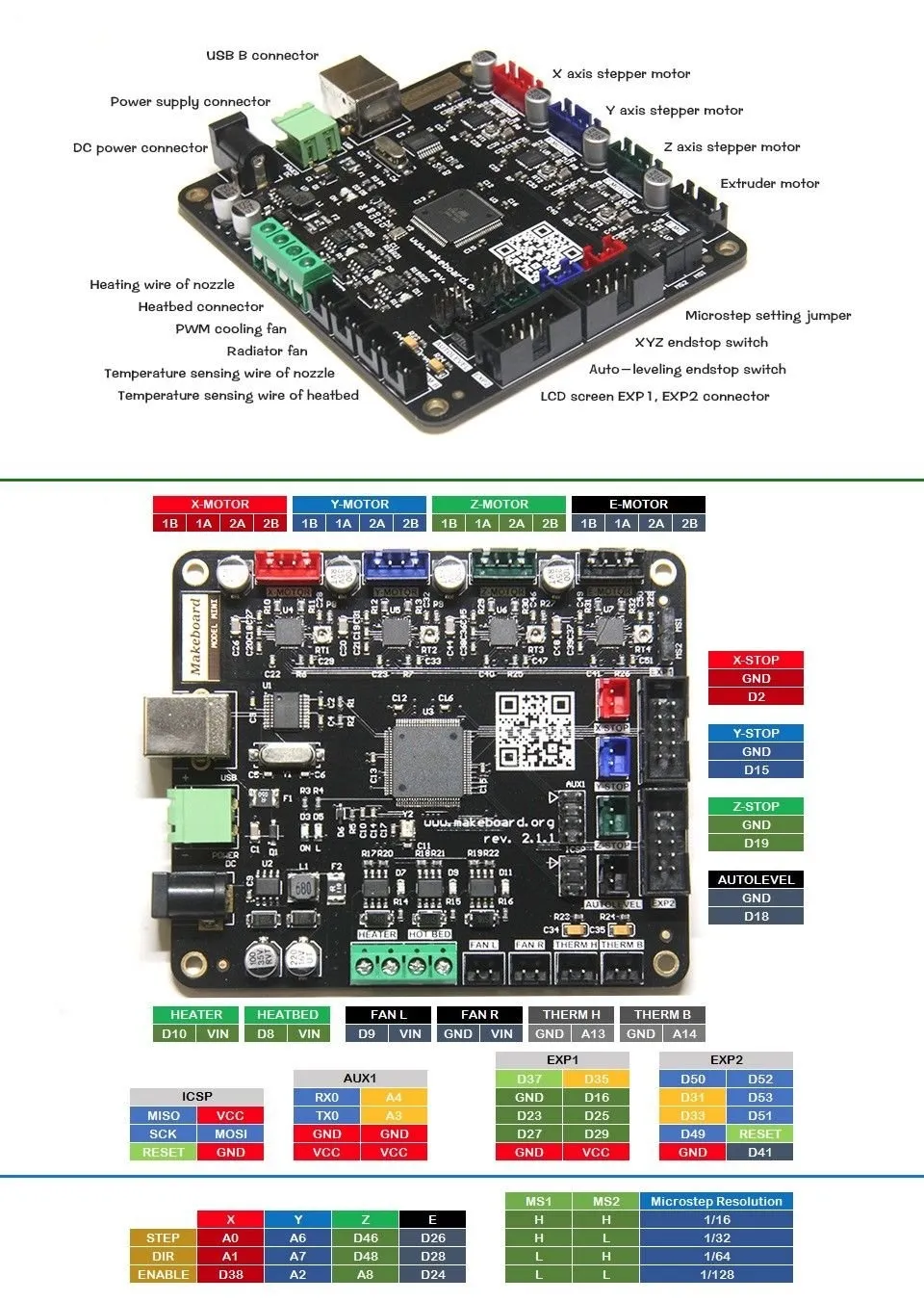

Electronics and Control Board

The control board is the brain of your Tevo Tarantula, coordinating all the printer’s functions. It receives commands from the firmware and controls the stepper motors, hotend, bed, and other components. The control board is equipped with a microcontroller and various connectors for all the printer components. Upgrading to a more powerful control board can enable advanced features and improve print quality. The firmware on the control board is responsible for interpreting G-code files and controlling the printer’s operations. Keep your firmware updated to the latest version to benefit from bug fixes and performance improvements. Monitor the electronics to prevent overheating and ensure proper operation. A well-maintained control board is vital for reliable printing and overall printer performance.

Power Supply Unit (PSU)

The power supply unit (PSU) provides the necessary electrical power to the printer. It converts AC power from the wall outlet to DC power for the various components. Ensure that your PSU has sufficient wattage to handle the printer’s power demands. Upgrading your PSU may be necessary if you add power-hungry components, such as a heated bed. A reliable power supply is essential for the safety and functionality of your printer. Check the voltage settings on your PSU to ensure they match your local power supply. Inspect the power supply regularly for any signs of damage. Avoid overloading your PSU. It protects the components from power surges and helps to keep the printer safe.

Mechanical Components and Assembly

The mechanical components of the Tevo Tarantula are essential for its structural integrity and movement precision. These include the frame, belts, pulleys, bearings, and rods. Proper assembly and maintenance of these parts directly influence the quality of your prints. Regular checks for loose screws, worn belts, and smooth linear movement are crucial. Upgrading these mechanical components can enhance the printer’s performance and lifespan. Investing time in assembling and maintaining these parts will result in more reliable and higher-quality prints. A well-maintained printer ensures stability and accuracy.

Belts and Pulleys

Belts and pulleys are responsible for the precise movement of the print head and bed. The belts are typically made of rubber and are driven by the stepper motors. Pulleys guide the belts and ensure smooth movement. Maintaining proper belt tension is critical for print accuracy. Over-tightening can cause wear and tear, while loose belts can result in print inaccuracies. Regularly inspect the belts for wear and tear, and replace them if necessary. Check the pulleys for any signs of damage or misalignment. Correct belt tension and smooth pulley operation are essential for achieving precise and reliable prints. Proper maintenance extends the lifespan of these components.

Bearings and Rods

Linear bearings and smooth rods enable smooth movement of the print head and bed along the X, Y, and Z axes. They reduce friction and ensure accurate positioning. Regularly lubricate the rods and bearings to maintain smooth movement and reduce wear. Using appropriate lubricant will help the printer. Worn or damaged bearings can cause print imperfections and should be replaced promptly. Ensure that the rods are straight and free from any debris. Maintaining the condition of these components is crucial for consistent and high-quality prints. Frequent inspection of your 3D printer bearings and rods helps to identify potential problems early on.

Electronics Explained

The electronics in the Tevo Tarantula control and coordinate all the printer’s functions, making them the heart of the machine. Understanding the main electronic components, such as the control board, stepper motor drivers, and power supply, helps with troubleshooting and upgrades. Familiarity with the firmware and software that drive the printer allows for customization and optimization of performance. Regular maintenance of the electronics is essential to ensure the reliable and safe operation of your printer. Inspecting and maintaining these components will improve the longevity and enhance the performance of your Tevo Tarantula. This allows you to diagnose any issue related to the electronic components.

Firmware and Software

Firmware is the software that runs on your printer’s control board. It interprets G-code commands and controls the printer’s movements, temperature, and other functions. Popular firmware options include Marlin. Staying up-to-date with the latest firmware versions provides bug fixes, performance improvements, and new features. Software such as slicing software converts 3D models into G-code files. It is essential to choose the right slicing software to match your printer’s specifications. Configure the settings in your slicing software to optimize print quality and speed. Familiarize yourself with the software and the firmware to make the most of your 3D printer.

Calibration and Maintenance

Proper calibration and regular maintenance are essential for maintaining the performance and longevity of your Tevo Tarantula. Regular maintenance extends the lifespan of your printer and ensures you get the best possible print quality. The calibration steps ensure accurate and consistent prints. Regularly performing these steps will minimize issues and increase the quality of your print. By following the maintenance checklist and addressing common issues, you will be able to keep your printer in top condition.

Regular Maintenance Checklist

A regular maintenance checklist ensures your Tevo Tarantula operates at its best. This should include these steps; Inspect the frame and tighten all screws. Check the belt tension. Lubricate the rods and bearings. Clean the nozzle and hotend. Level the bed. Check the wiring and connections. Update the firmware. Regular maintenance prevents unexpected failures and extends the life of the printer. Adhering to these practices promotes a smooth printing experience. Regular maintenance prevents issues and extends the life of your printer.

Troubleshooting Common Issues

Understanding common issues and how to troubleshoot them is essential for any 3D printer user. This section addresses some frequently encountered problems and offers solutions to get your printer back up and running. This knowledge is crucial for maintaining your printer and minimizing downtime. By identifying and resolving these issues efficiently, you can ensure reliable performance and maintain a consistent printing process. This list helps you solve the common issues you might face when using the Tevo Tarantula.