Top 5 Tevo Tarantula Arduino Board DIY Upgrades

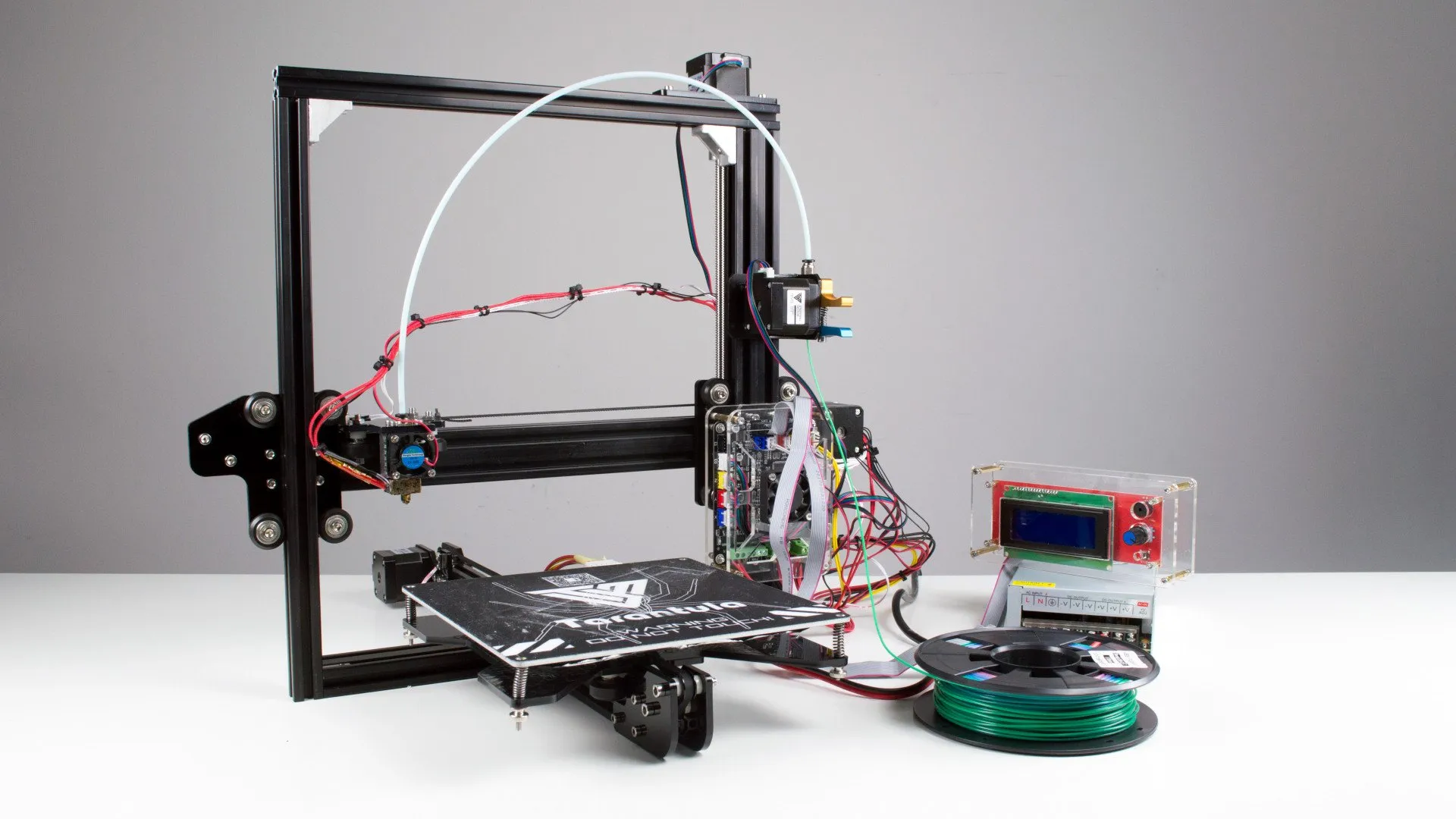

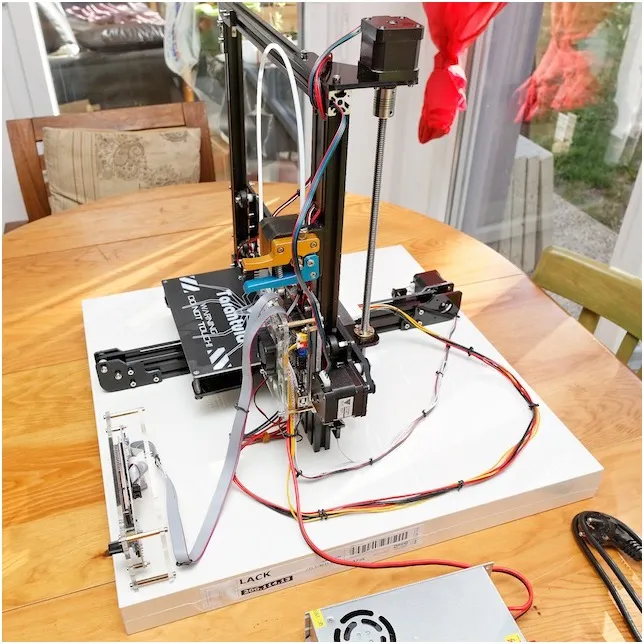

The Tevo Tarantula is a popular entry-level 3D printer, known for its affordability and open-source design, which makes it a fantastic platform for tinkering and upgrades. The Arduino board at its core offers flexibility, and with a few strategic DIY enhancements, you can significantly improve its performance, reliability, and overall user experience. This guide highlights the top 5 essential upgrades you can make to your Tevo Tarantula 3D printer, focusing on practical improvements that translate to better prints and a more enjoyable hobby. These upgrades are relatively easy to implement, even for beginners, and the results are well worth the effort. Get ready to elevate your 3D printing game!

Upgrade 1: Enhanced Bed Leveling System

Bed leveling is the cornerstone of successful 3D printing. An uneven bed leads to poor first-layer adhesion, warping, and failed prints. Upgrading your Tevo Tarantula’s bed leveling system is often the first and most impactful modification you should consider. This upgrade ensures that your prints adhere correctly and start on a solid foundation. There are several ways to enhance bed leveling. You can upgrade to a BLTouch sensor for automatic bed leveling or use manual bed leveling. Each option will enhance the printing experience.

Why Bed Leveling Matters

Proper bed leveling is critical for ensuring the first layer of your print adheres correctly to the print bed. If the bed is not level, the nozzle may be too close to the bed in some areas and too far away in others, leading to poor adhesion, warped prints, or even nozzle clogging. A well-leveled bed ensures consistent layer adhesion and reduces the likelihood of print failures. With the Tevo Tarantula Arduino board, this is simple to achieve with some extra components.

Leveling Upgrade Options

For manual leveling, consider adding bed springs. Replace the original springs with stiffer ones to maintain bed stability. Alternatively, you can upgrade to a BLTouch sensor for automatic bed leveling. This sensor measures the distance between the nozzle and the bed at multiple points, allowing the printer to automatically compensate for any bed irregularities. This upgrade can significantly reduce the time spent leveling manually and increase the success rate of your prints. Images of bed leveling modifications are useful when working with the Tevo Tarantula Arduino board.

Upgrade 2: Filament Runout Sensor

Running out of filament mid-print is a frustrating experience, often resulting in wasted time and material. A filament runout sensor detects when your filament spool is nearing empty and pauses the print, allowing you to load new filament and resume where you left off. This simple addition can save you from numerous failed prints. By using the Arduino board, you can easily install a filament sensor and have the Tevo Tarantula automatically pause, helping to get the best results.

The Importance of Filament Monitoring

Filament monitoring is essential for unattended printing, particularly for longer prints. Without a sensor, the printer will continue to extrude air if the filament runs out, leading to a failed print and wasted time. A filament runout sensor prevents this by pausing the print when the filament is depleted, giving you the opportunity to swap spools and continue the print. These features are especially useful when using the Tevo Tarantula Arduino board.

Choosing a Filament Sensor

There are a few different types of filament runout sensors available. Optical sensors use an infrared beam to detect the presence of filament, while mechanical sensors use a physical switch triggered by the filament. Both types are relatively easy to install and connect to the Arduino board on your Tevo Tarantula. Select a sensor that fits your budget and print style, and ensure it is compatible with your printer’s firmware. These components will increase print quality and printer safety.

Upgrade 3: Improved Cooling Fan

Adequate cooling is crucial for high-quality 3D prints. An improved cooling fan helps solidify the extruded plastic quickly and evenly, preventing warping, overhang issues, and other print defects. The stock fan on the Tevo Tarantula may not always provide sufficient cooling, especially when printing with materials that require faster cooling rates. Upgrading the cooling fan is one of the most effective upgrades to improve your print quality.

Benefits of Better Cooling

Improved cooling leads to several benefits, including better bridging, sharper overhangs, and reduced warping. The cooling fan directs airflow towards the printed part, allowing the plastic to cool and solidify rapidly. This is especially important for printing detailed parts, where precise cooling is essential. Images of enhanced cooling fan configurations for the Tevo Tarantula Arduino board are helpful for visualizing the upgrade.

Fan Types and Installation

Consider upgrading to a more powerful fan or adding a dual-fan setup for improved cooling performance. Ensure the fan is correctly mounted and directs airflow towards the printed part, not the hot end. Before installing a new fan, check the voltage and current requirements to ensure it is compatible with your printer’s power supply. Modifying the cooling system will allow you to optimize the output of your Tevo Tarantula Arduino board 3D printer.

Upgrade 4: Direct Drive Extruder

A direct drive extruder places the extruder motor directly above the hot end, reducing the distance the filament has to travel. This configuration offers several advantages, including better control over filament extrusion, improved retraction performance, and the ability to print with flexible filaments. While this upgrade can be slightly more complex than the others, the resulting improvements in print quality and material compatibility are significant.

Advantages of Direct Drive

The primary advantage of a direct drive extruder is improved filament control. The shorter distance between the extruder and the hot end reduces the likelihood of filament jams and allows for more precise retraction, leading to cleaner prints with less stringing and oozing. A direct drive setup also makes it easier to print with flexible filaments, as the filament is less likely to buckle or deform. With the Arduino board, a direct drive setup will enable more advanced features.

Choosing a Direct Drive Kit

There are various direct drive kits available for the Tevo Tarantula. When choosing a kit, consider factors such as compatibility, ease of installation, and the type of extruder motor. You may need to modify your printer’s firmware to accommodate the new setup. Research different kits to find one that suits your needs and skill level. Images of a direct drive system for the Tevo Tarantula are great visual aids for this upgrade.

Upgrade 5: Silent Stepper Motor Drivers

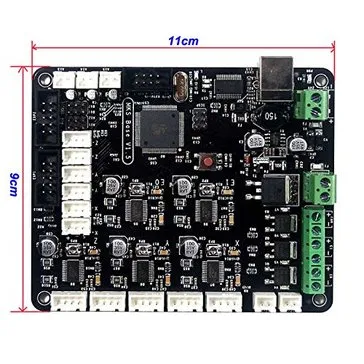

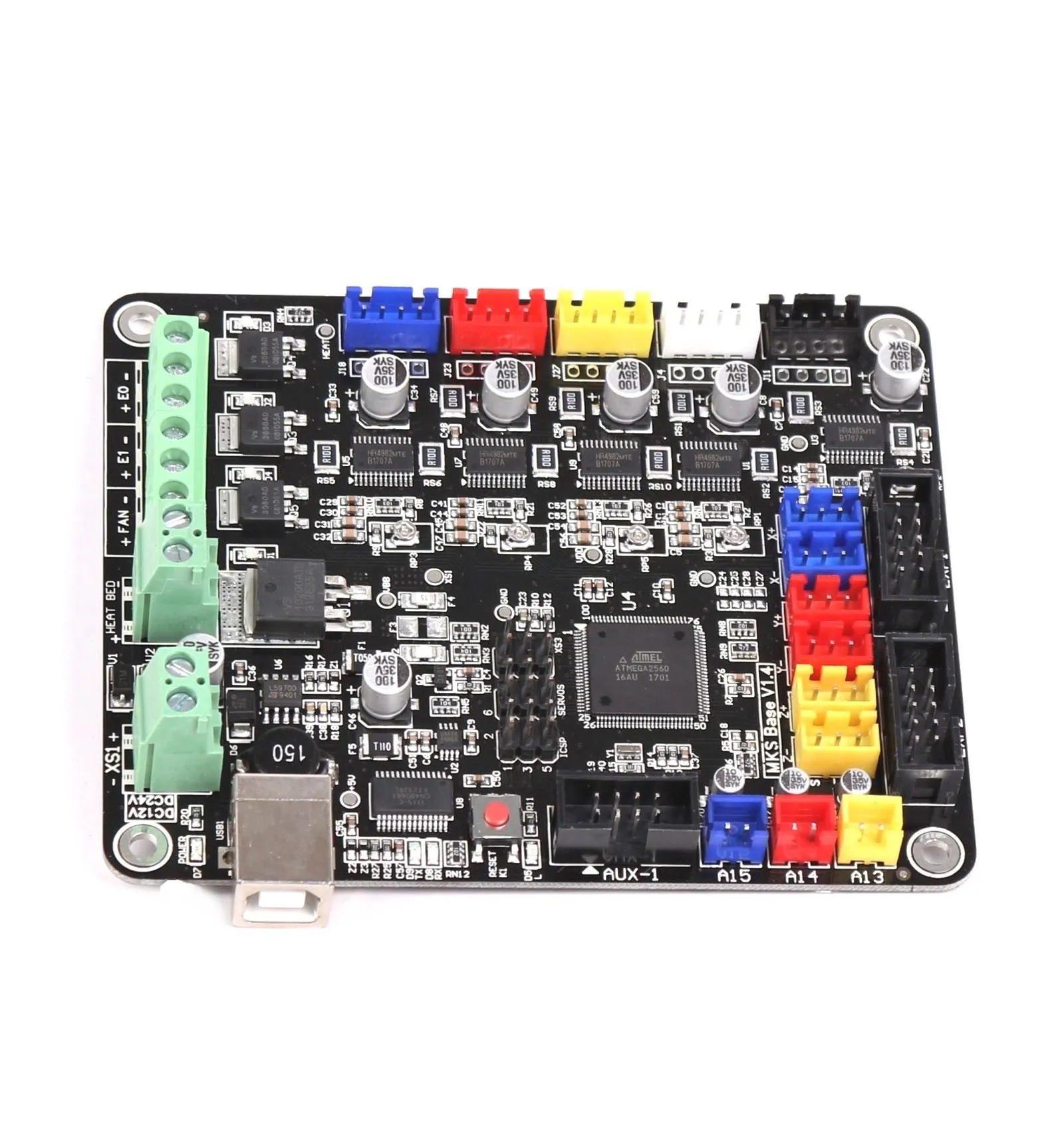

3D printers can be noisy due to the stepper motors. Upgrading to silent stepper motor drivers can dramatically reduce the noise levels of your Tevo Tarantula, making it more pleasant to use. This is a relatively simple upgrade that can significantly improve your printing experience, especially if you print in a shared space. The Arduino board can be modified with drivers that will reduce the sound output of the printer.

Reducing Printer Noise

The stock stepper motor drivers on the Tevo Tarantula can generate a significant amount of noise. Silent drivers utilize advanced technology to minimize the noise generated by the stepper motors, resulting in a quieter printing experience. This is especially beneficial if you work or live near your printer. The Arduino board is compatible with different types of drivers that will help reduce the noise level.

Installing Silent Drivers

Installing silent drivers is relatively straightforward. You will need to replace the existing drivers on the Arduino board with the new, silent ones. Make sure to check the compatibility of the drivers with your printer’s board and the required voltage. You may need to adjust the driver’s current settings for optimal performance. Several online tutorials and guides can help you with the installation process. Pictures of the Arduino board modifications are helpful for installing the drivers.

Conclusion

Upgrading your Tevo Tarantula Arduino board 3D printer with these five DIY modifications will significantly enhance your printing experience. From improving bed leveling and filament monitoring to boosting cooling and reducing noise, these upgrades offer tangible benefits in terms of print quality, reliability, and usability. Each upgrade is a rewarding project, allowing you to learn more about your printer and refine your 3D printing skills. By implementing these upgrades, you can unlock the full potential of your Tevo Tarantula, creating amazing 3D prints and enjoying the exciting world of 3D printing.